Description

1. Power-On Procedure

-

Connect to a 380V, 50Hz power supply.

-

Turn on the operation and lighting switches.

-

Ensure that both the fan and the lighting are functioning properly.

-

At this point, the air shower room is in its initial state, and personnel can proceed with normal operations.

2. Entry and Exit Procedures

Entry Procedure:

-

Press the manual button to open the entrance door.

-

The entrance door opens automatically; personnel or goods enter the air shower room.

-

If the anti-pinch sensor on the inner side of the entrance door does not detect any person or object within 5 seconds, the entrance door will close automatically.

-

Personnel or goods enter the air shower sensing area.

-

The air shower initiates, blowing air at a speed of 20–25 m/s.

-

The air shower duration is adjustable between 10–99 seconds; the default factory setting is 15 seconds.

-

Upon completion of the air shower, the exit door opens automatically.

-

Personnel or goods exit the air shower room.

-

If the anti-pinch sensor on the inner side of the exit door does not detect any person or object within 5 seconds, the exit door will close automatically, completing the process.

Exit Procedure:

-

Press the manual button to open the exit door.

-

The exit door opens automatically; personnel or goods enter the air shower room.

-

If the anti-pinch sensor on the inner side of the exit door does not detect any person or object within 5 seconds, the exit door will close automatically.

-

The entrance door opens automatically.

-

Personnel or goods exit the air shower room.

-

If the anti-pinch sensor on the inner side of the entrance door does not detect any person or object within 5 seconds, the entrance door will close automatically, completing the process.

3. Precautions

-

After the air shower room is powered on, the two doors are interlocked. It is strictly prohibited to forcibly open the other door when one door is not completely closed.

-

It is strictly forbidden to open the doors during the air shower process (until the air shower stops). In case of emergency, press the emergency stop switch to halt the air shower before opening the door.

-

The emergency stop switch will automatically reset after 3–4 minutes, and the system will enter sleep mode. Press any key to restore the system to normal operation.

-

During maintenance (or when opening the panel), ensure safety by turning off the main power switch and removing the fuse. Confirm that there is no electrical power before proceeding with any work.

-

After the air shower process is complete, it is strictly prohibited to forcibly open the front door.

-

The air shower room should be operated by designated personnel. After positioning the air shower nozzles, non-operating personnel should not reposition them.

4. Control Panel Screens

First Screen: Main Operation Screen

-

Pressing the “ESC” button will disconnect all outputs (only effective on the first screen).

-

Pressing the “ALM” button will disconnect the lighting output (only effective on the first screen).

-

When the power supply is connected, the power indicator light will illuminate (only effective on the first screen).

-

When the fan is operating, the work indicator light will illuminate (only effective on the first screen).

Use the up/down keys to navigate to the second screen.

Second Screen: Parameter Setting Screen

-

Press “0” to prompt for a password, then press the “ENT” key. The default password is “999”. Use the direction keys to input the password (direct numeric input is not supported). After entering the password, press “ENT” to confirm. Then press “ESC” to return to the second screen. Press the “SET” key to select the data entry position, input the desired value, and press “ENT” to confirm.

-

Air shower time setting range: 0.3–999.9 seconds.

-

Lighting time setting range: 18–3600 seconds.

-

Exit door delay setting range: 0.1–20 seconds.

-

Entrance door delay setting range: 0.3–20 seconds.

-

If the entered data is outside the specified range, a buzzer will sound as a warning.

Use the up/down keys to navigate to the third screen.

Third Screen: Configuration Screen

-

Select the data entry position, input the desired value, and press “ENT” to confirm. After successfully modifying the data, press the “SET” key until the cursor disappears.

-

Production quantity setting range: 1–99.

-

Production date setting range: 2000–9999.

-

If the entered data is outside the specified range, a buzzer will sound as a warning.

Use the up/down keys to navigate to the fourth screen.

Fourth Screen: Fault Diagnosis Screen

-

When the entrance door is closed, the entrance door magnetic sensor indicator light changes from white to black. When the exit door is closed, the exit door magnetic sensor indicator light changes from white to black. When the photoelectric switch is activated, its indicator light changes from white to black.

-

When the entrance door’s electric lock is powered, its indicator light changes from white to black. When the exit door electric lock is powered, its indicator light changes from white to black. When the air shower is operating, its indicator light changes from white to black. When the lighting is on, its indicator light changes from white to black.

Use the up/down keys to navigate to the fifth screen.

Fifth Screen: Consumables Size Screen

-

Select the data entry position, input the desired value, and press “ENT” to confirm. After successfully modifying the data, press the “SET” key until the cursor disappears.

-

Pre-filter size setting range: Maximum 2000×2000×500 mm; Minimum 10×10×5 mm.

-

HEPA filter size setting range: Maximum 2000×2000×1000 mm; Minimum 10×10×5 mm.

-

Lighting setting range: 1–99.

-

If the entered data is outside the specified range, a buzzer will sound as a warning.

You can use the up/down keys to navigate to any screen. After successfully modifying the data, press the “SET” key until the cursor disappears. Press “1”, then press the down arrow (▼) to navigate to the password deactivation option. Press “ENT” to confirm that the password has been deactivated. Exit to the first screen, press the “ESC” emergency stop button once to initiate an emergency stop, then press it again to release the emergency stop. All settings will then be successfully applied.

5. Common Faults and Troubleshooting

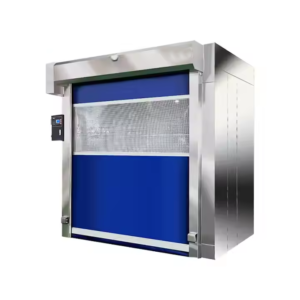

If the rapid roller shutter air shower room exhibits any abnormalities, please refer to the following table for self-inspection. If the issue cannot be resolved, promptly contact our company’s after-sales service department for maintenance assistance.

| Fault Phenomenon | Possible Cause | Solution |

|---|---|---|

| Low Wind Speed | HEPA filter clogged due to prolonged use | Replace the HEPA filter |

| Pre-filter clogged due to prolonged use | Replace the pre-filter | |

| Fan Not Operating | Loose or disconnected power connection | Check and secure the power connections |

| Damaged internal electrical components in the control box | Replace the damaged components | |

| Fan has been running for an extended period | Replace the fan | |

| PLC control system malfunction | Inspect and repair the PLC system | |

| Fan Does Not Stop | Time relay malfunction | Repair or replace the relay board |

| Intermediate relay malfunction | Replace the intermediate relay | |

| Lighting Malfunction | Damaged fluorescent lamp | Replace the lamp |

| PLC control system malfunction | Inspect and repair the PLC system | |

| Both Doors Interlocked | Faulty electric lock or sensor, PLC program error | Replace the faulty components or reprogram the PLC |